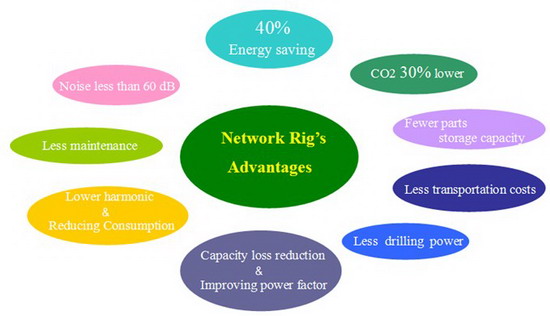

Energy saving, environmental protection, efficient, this is the network rig. Network rig can reduce the noise, save drilling cost, reduce the labor intensity of workers, not only save money, fuel-efficient, labor-saving, but also improve the safety level. Network rig, your good helper.

1. System components:

AC network rig system is based on the original diesel generator power supplying AC electric on the electric control system, and not changing the original power supply reliability, under the premise of taking the electric power grid as a power supply substitute of the formation of the diesel generator power supply and rig electrical control system.

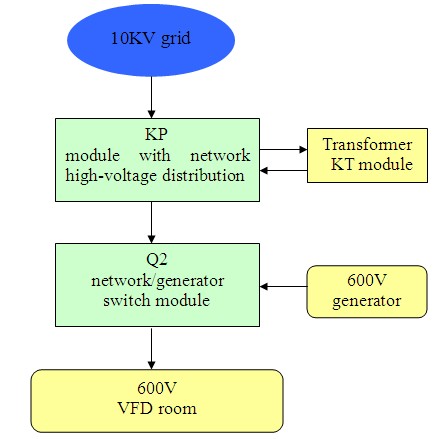

Our electricity system has the protection, control, monitoring and measurement, and the function is exactly same with the LDB signal system with high pressure room. AC network rig consists of six components, including: 10kv grid, 600V generator, VFD room, one KP module with network high-voltage distribution, one transformer KT module and one two-end network switch Q module. As below:

When using the turbodrill, it is a need to have a larger active power and reactive power, voltage fluctuation is also more serious, so that we can use circumscribed reactive compensation and three end type module TSF network switching device to increase the amount of reactive power compensation and improve the quality of voltage. As below:

2. Application

This network system is suitable for network transformation project of ZJ70DB fully electric variable-frequency drilling rig and ZJ70D fully electric AC drilling rig. After using this product, drilling rig no longer use diesel generator but power of 10kV grid thus lower diesel consumption of high price, reduce CO2 emission and greatly lower noise of well site. The direct benefit using power instead of diesel is able to reduce (40 to 60)% drilling energy consumption cost, if the cost, like operation, maintenance, spare parts, fuel oil transportation etc of diesel generating set is accounted, the overall reduction of drilling power cost is around (40~65)%.

3. Basic mechanical design feature

| Table 1 main technical parameters of AC network rig’s network system |

| 10kV AC electric network system essential parameter |

| Model | DH.KYB1F-10/0.6 | Transformer capacity | 2500~4000 kV |

| Max. rated voltage | 12kV | Capacity of MSVC | 1200kVAr |

| Rated operational voltage | 10kV | Harmonic compensation current | 200~600A |

| Shell coefficient | K=10 | Dimensions | L11570*W2900*H2940 |

| Protection level of distribution room | IP55D | Total weight | 26t |

| The default configuration main parameters of transformer |

| HJB | SCZ10-2500-10/0.6 | Rated capacity | 2500kVA |

| On-load changer range | 10±4*2.5%/0.6kV | Impedance voltage | 6.0% |

| resistance to heat class | H | Winding coupling group | D,d-0 |

| high-voltage switch cabinet main parameters |

| Model | TZ.XGN1-12/630-20 | Rated voltage | 10kVA |

| XGN15-12FV/630-20 | Rated current | 630A |

| Rated short-circuit breaking current | 20kA | Short-term resistance current | 20kA/4s |

| Table 2 Different rig and transformer capacity, reactive power compensation and harmonic compensation current capacity supporting table |

| Rig model | 120DB | 90DB | 70DB | 70D |

| Transformer capacity (kVA) | 4000 | 3150 | 2500 | 2500 |

| Reactive power compensation capacity (kVAr) | 2000 | 1600 | 1200 | 2000 |

| Filter harmonic compensation current (A) | 800 | 600 | 300 | 600 |

| | | | | |

|